Added the function of saving a flat pattern of a straight and truncated cone to a dxf file permission to write the file is required.

Sheet metal cone calculator metric.

Enter top width bottom width and height of the cone see diagram and hit calculate to draw a full scale printable pattern template to mark out the cone.

Metal weight calculator online free steel weight calculator.

The picture below illustrates the task.

If you liked this perhaps you ll like my latest project.

See volume calibration templates to mark fluid volumes on cone.

Pick a paper size you can mix and match paper and units.

When it comes to curved steel finding the precise measurements is a challenging undertaking.

For creating a cone from sheet metal or any flat material.

Calculates the measurements for the pattern to construct a flat top cone.

Pick a unit to be used for all three dimensions.

Calculate the weight of a steel beam bar tube profiles channels or a simple metal sheet.

To mark holes or lines around the cone check holes or lines and enter number of incremetns enter hole slant height up slanting edge of the cone and hole diameter and hit draw.

Cells on the right will output the desired values.

Enter the two diameters of your cone section.

Enter the height and click calculate.

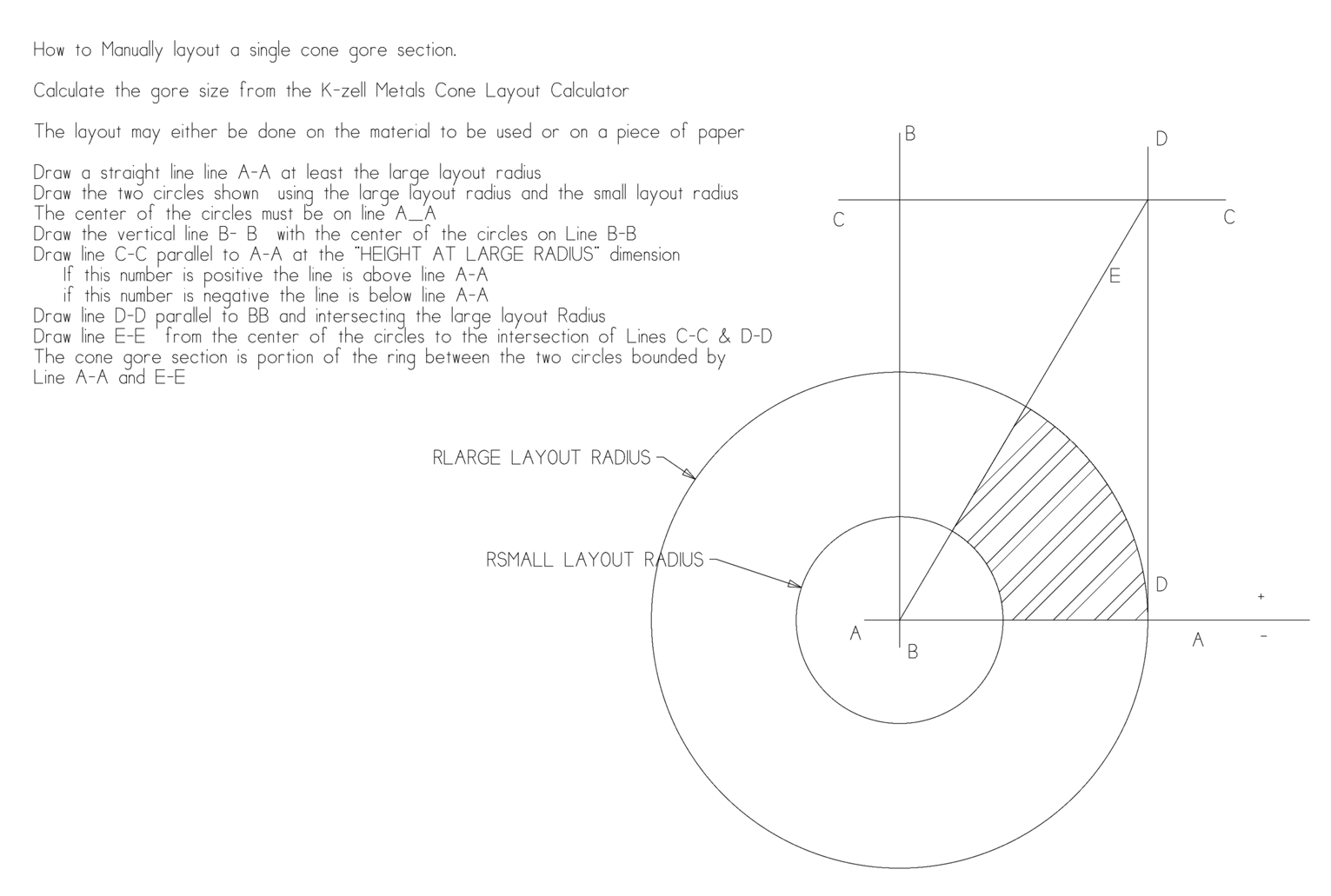

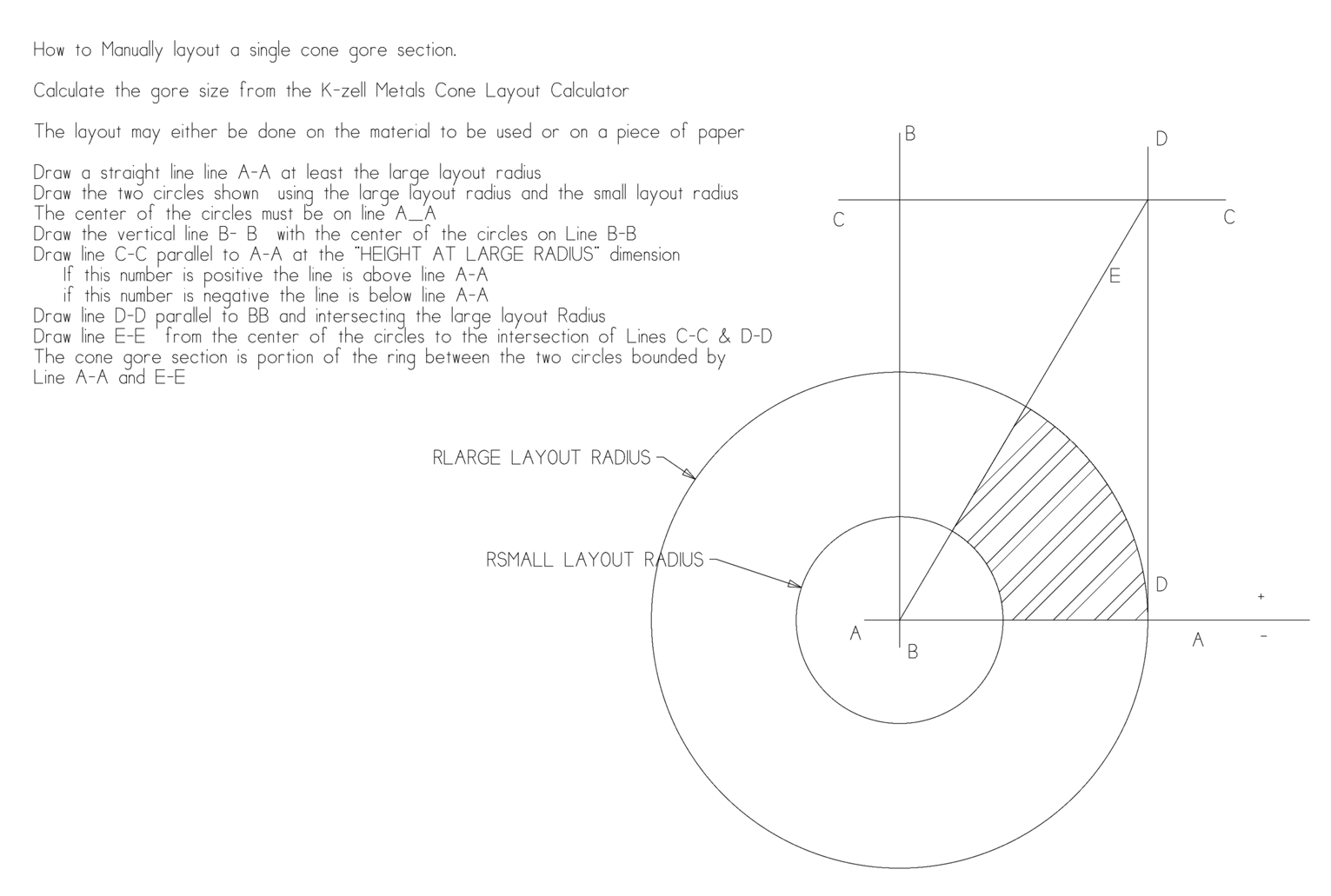

View the cone instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections.

The flat pattern of a cone is an application that calculates the parameters for a development of a right oblique or truncated cone.

We have radius of the lower base radius of the upper base in case of truncated cone and cone height.

Calculator computes parameters of right circular cone or truncated right circular cone development.

The layout may either be done on the material.

To solve this cmrp provides easy to use measurement calculators.

It does not matter which one is the big one.

Has pre entered densities for dozens of commonly used metals and metal alloys like steel aluminum nickel iron copper cadmium gold silver etc.

You only have to insert interior angle flange lengths k factor inside radius and material thickness.

Length a mm length b mm length c mm arc angle degrees radius r1 mm radius r2 mm hi.

It allows you to determine either the size of raw material needed or the number of gore sections to fit on your available material.

One of them can be 0.

Aligned behaviour for business goals.

The program will do the right thing.

The curved steel cone calculator from chicago metal rolled products makes it easy to find the precise curved steel cone dimensions you need.