Click the create relief tool button on the sheet metal ribbon tab.

Relief ratio sheet metal.

Right click the sheet metal feature in the featuremanager design tree and select edit feature.

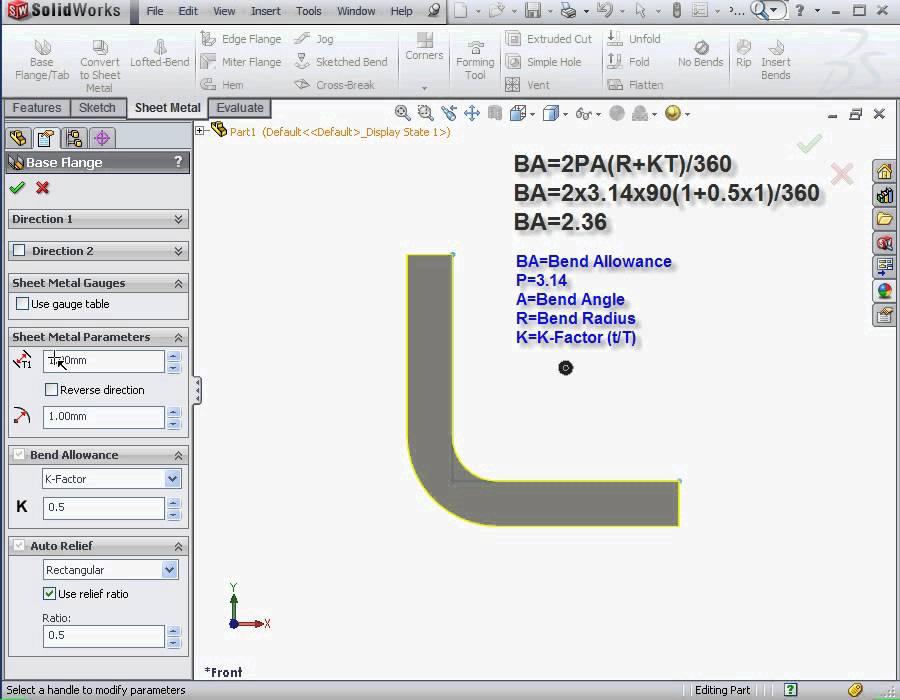

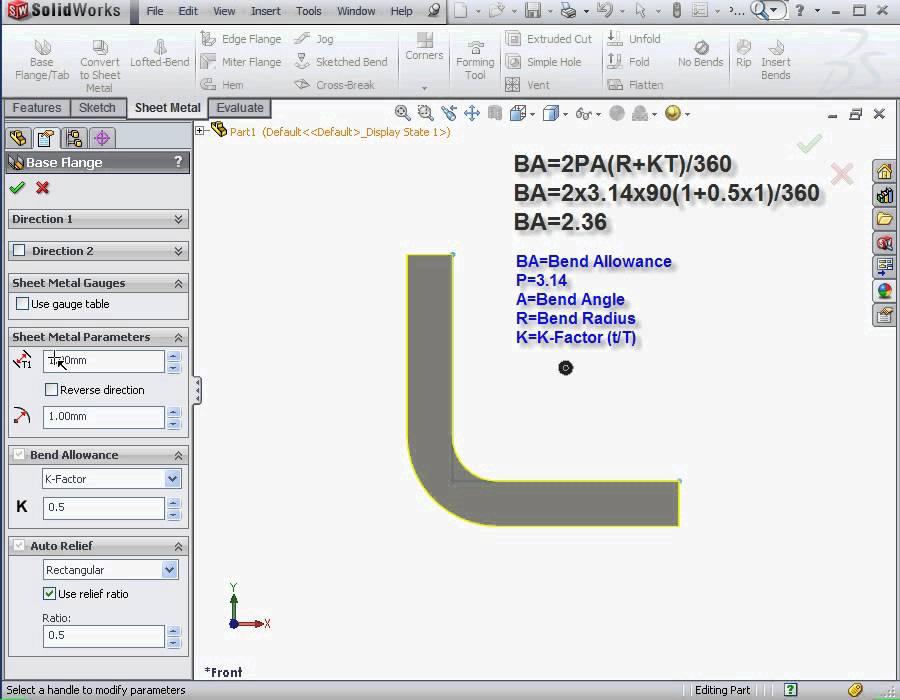

The value of the relief ratio must be between 0 05 and 2 0.

To eliminate this a bend relief is added so the edge of the sheet metal is perpendicular to the bend.

Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation the radius can be near zero for thin sheet metal.

Once the base flange feature is created this setting will be.

The length ratio 3 2 fig.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

When sheet metal makes a transition from a bend to a flat surface or to another bend it tends to tear depending on the geometry.

Enter relief size by bend radius ratio or force bend reliefs.

Do one of the following.

It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii.

The minimum bend radius data shown in these charts is measured to the inside of the bend.

Type smreliefcreate in the command bar.

For a 3 width ratio when the part is 1 mm in thickness the width of the slot will be 3 mm.

In the propertymanager under auto relief change the type of relief cut.

The width of the relief cut and the depth it extends past the bend will be determined by relief ratio part thickness.

If you select rectangular or obround specify the relief ratio.

6 shows when the ratio to thickness is used in a obround relief the width ratio has more influence on the shape of the relief than the length ratio.

Bend radii minimum bend sizes.

The higher the value the larger the size of the relief cut added during insertion of bends.

Choose create relief in the sheet metal menu.

The higher the value the larger the size of the relief cut added during insertion of bends.

Ratios are configured for the hard material condition.

User can configure the ratio based on the material.

This check computes inside bend radius and checks the ratio of bend radius to sheet thickness.

Examples of i tear.

Select an item see the note below.

The value of the relief ratio must be between 0 05 and 2 0.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching cutting stamping and bending.

7 only affects the relief within a narrow margin.

Protocase tech tip video.

Sheet metal in solidworks sheet metal parts are generally used as enclosures for components or to provide support to other.

In general a minimum bend relief is equal to the material thickness plus the inside bend radius.

3d cad files are converted into machine code which controls a machine to precisely cut and form the sheets into the final part.